Product list

| CODE |

PRODUCT |

UNIT |

|

|---|---|---|---|

| PRC107E | Water softening and preparation of pure water, hydrometallurgy, sugar refining, pharmaceuticals, glutamic acid preparation, and as dehydrating agent and catalysts. Food grade. | liter | More… |

| PRC107H | Primarily used in the cation stage of demineralization plants used in industrial water treatment employing coflow regeneration. | liter | More… |

| PRA420 | Regeneration / Efficient Demineralization / Silica Removal Preparation of pure water, sugar liquor decolorization, separation and purification of biomedical products, extraction of radioactive elements. Gel Type 1 strong-base anion exchanger with both high operating capacity and the ability to achieve low residual silica levels |

liter | More… |

| PRA620 | Regeneration / Efficient Demineralization/ Silica Removal Preparation of pure water, sugar liquor decolorization, separation and purification of biomedical products, extraction of radioactive elements. | liter | More… |

| PRFC107 | Demineralization / Softening – Uniform Beads | liter | More… |

| PRFA420 | Regeneration / Efficient Demineralization – UniformSized | liter | More… |

| PRA500 | Organic compounds removal | liter | |

| PRMB400 | Mix bed resin. It is resin mixture for direct purification of water. It is suitable for use in regenerable or non-regenerable cartridges and in large ion exchange units. | liter | |

| Ultramix | Universal filtration media for hardness, iron, manganese and organic compounds removal | liter | More… |

Packing |

|

|---|---|

| 1 Pallet = 42 Bags | 1 Bag = 25 Liters |

|

|

Purolex PRC107E

Purolex PRC107E is a high purity, premium grade, pre-washed, strong acid gel-type cation exchange resin (high purity bead form conventional gel polystyrene sulfonate cation exchange resin), designed especially for potable waters, beverages and other water processing of food.

The resin can also remove dissolved iron, manganese, and suspended materials through the filtering action of the softening bed. In addition, it is a cost-effective product for treating any household water.

Technical characteristics

| Ionic Form as Shipped | Na+ |

| Functional Group | Sulfonic acid |

| Polymer Structure | Crosslinked Polystyrene Divinylbenzene |

| Appearance | Amber, clear spherical beads |

| Whole Bead Count | 90% min. |

| Temperature Limit | 120°C (250°F) |

| Total Capacity (min.) | 1.9 eq/l (41.5 Kgr/ft3) (Na+ form) |

| Total Exchange Capacity, Na+ form | |

| Swelling Na+ → H+ | 8% max |

| Ca++ → Na+ | 10% max |

| Particle Size Range | 315 – 1290 µm |

| Moisture Retention | 45 – 50 % (Na+ form) |

| <300 µm (max.) | 1 % |

| Uniformity Coefficient (max.) | 1.6 |

| Reversible Swelling Ca2+ → Na+ | 8 % |

| Reversible Swelling, Na+ → H+ (max.) | 10 % |

| Specific Gravity | 1.27 |

| Shipping Weight (approx.) | 800 – 840 g/l (50 – 52.5 lb/ft3) |

Hydraulic properties

Pressure drop

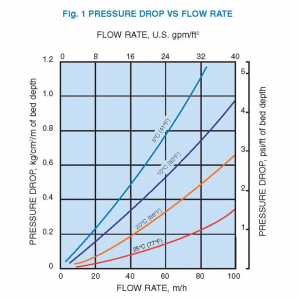

The pressure drop (headloss) across a properly classified bed of ion-exchange resin depends on the particle size distribution, bed depth, and void volume of the exchanger; and on the flowrate and viscosity (and hence on the temperature) of the influent solution. Anything affecting any of these parameters, for example the presence of particulate matter filtered out by the bed, abnormal compaction of the resin bed, or the incomplete classification of the resin will have an adverse effect, and result in an increased headloss. Typical values of pressure drop across a bed of Purolex PRC107E are given for a range of operating flow rates in Fig. 1.

Backwash

During upflow backwash, the resin bed should be expanded in volume by between 50 and 75%, in order to free it from any particulate matter from the influent solution, to clear the bed of bubbles and voids, and to reclassify the resin particles as much as possible, ensuring minimum resistance to flow. Backwash should be commenced gradually to avoid an initial surge with consequent carryover of resin particles. Bed expansion increases with flow rate and decreases with temperature, as shown in Fig. 2, above. Care should always be taken to avoid resin loss by accidental overexpansion of the bed.

What’s next?

Contact us for more information

Find a distributor in your country